- Ti Mosfet Vs

- Ti Mosfet Calculator

- Ti Mosfet Driver

- Ti Mosfet Circuit

- High Power Mosfet

- Ti Mosfet Driver Application Note

by Majeed Ahmad

So all of TI's MOSFETs are done at 0.1 millihenry inductor value. And that's because the higher the Avalanche Current, the more stressful the test. And we want to screen out as many weak devices as we can during final test. But this isn't just the value that we use during final test before the FET goes into production. Power MOSFETs are controlled devices with a parasitic/bonus “body diode”. MOSFETs switch quickly with low on-state resistance. Power MOSFETs can often replace diodes for higher efficiency.

High temperatures and operating conditions outside the safe operating area can sabotage MOSFETs used in switching circuits.

The MOSFET (metal-oxide-semiconductor field-effect transistor) is a primary component in power conversion and switching circuits for such applications as motor drives and switch-mode power supplies (SMPSs). MOSFETs boast a high input gate resistance while the current flowing through the channel between the source and drain is controlled by the gate voltage. However, if not appropriately handled and protected, the high input impedance and gain can also lead to MOSFET damage caused by over voltage or too-high current.

First a few basics about avoiding MOSFET damage. Obviously, Vgs and Vds must both be within limits. The same for current, Id. There is also a power limit given by the maximum junction temperature. Basic values for the upper maximum on these parameters are given in the safe operating area (SOA) graph in the MOSFET datasheet. But it turns out, other thermal limits can apply. The SOA graph, for example, generally assumes an ambient temperature of 25° C with a specific junction temperature, usually below 150° C. But there are a variety of conditions that may cause high thermal gradients that may lead to expansion and cracking of the MOSFET die.

One factor to consider in this regard is that MOSFET thermal resistance is an average; it applies if the whole die is at a similar temperature. But MOSFETs designed for switch-mode power supplies can experience a wide temperature variation over different areas of their die. Optimized for on/off switching, they typically don’t work well in their linear region.

A typical failure mode for a MOSFET is a short between source and drain. In this case, only the source impedance of the power source limits the peak current. A common outcome of a direct short is a melting of the die and metal, eventually opening the circuit. For example, a suitably high voltage applied between the gate and source (VGS) will break down the MOSFET gate oxide. Gates rated at 12 V will likely succumb at about 15 V or so; gates having a 20-V rating typically fail at around 25 V.

All in all, exceeding the MOSFET voltage rating for just a few nanoseconds can destroy it. Device manufacturers recommend selecting MOSFET devices conservatively for expected voltage levels and further suggest suppressing any voltage spikes or ringing.

Too little gate drive

MOSFET devices are designed to dissipate minimal power when turned on. And the MOSFET must be turned on hard to minimize dissipation during conduction, otherwise it will have a high resistance during conduction and will dissipate considerable power as heat.

Generally speaking, a MOSFET passing high current will heat up. Poor heat sinking can destroy the MOSFET from excessive temperature. One way of avoiding too-high current is to parallel multiple MOSFETs so they share load current.

Many P- and N-channel MOSFETs are used in topologies involving an H- or L-bridge configuration between voltage rails. Here, if the control signals to the MOSFETs overlap, the transistors will effectively short-circuit the supply. This is known as a shoot-through condition. When it arises, any supply decoupling capacitors discharge rapidly through both MOSFETs during every switching transition, causing short but large current pulses.

The way to avoid this condition is to provide a dead time between switching transitions, during which neither MOSFET is on.

Over-currents even for a short duration can cause progressive damage to a MOSFET, often with little noticeable temperature rise before failure. MOSFETs often carry a high peak-current rating, but these typically assume peak currents only lasting 300 µsec or so. It is particularly important to over-rate MOSFETs for peak current when they switch inductive loads.

When switching inductive loads there must be a path for back EMF to freewheel when the MOSFET switches off. Freewheeling is the sudden voltage spike seen across an inductive load when its supply voltage is suddenly interrupted. Enhancement mode MOSFETs incorporate a diode that provides this protection.

High-Q resonant circuits can store considerable energy in their inductance and capacitance. Under certain conditions, this high energy causes the current to freewheel through the internal body diodes of the MOSFETs as one MOSFET turns off and the other turns on. (An intrinsic body diode is formed in the body-drain p-n junction connected between the drain and source. In N-channel devices, the body diode anode connects to the drain. The polarity is reversed in P-channel MOSFETs.) A problem can arise because of the slow turn-off (or reverse recovery) of the internal body diode when the opposing MOSFET tries to turn on.

MOSFET body diodes generally have a long reverse recovery time compared to the performance of the MOSFETs themselves. If the body diode of one MOSFET conducts when the opposing device is on, a short circuit arises resembling the shoot-through condition. The solution to this problem involves a Schottky diode and a fast-recovery diode. The Schottky diode connects in series with the MOSFET source and prevents the MOSFET body diode from ever being forward biased by the freewheeling current. The high-speed (fast recovery) diode connects in parallel with the MOSFET/Schottky pair. It lets the freewheeling current bypass the MOSFET and Schottky completely. This ensures the MOSFET body diode is never driven into conduction.

Transitions

A MOSFET dissipates little energy during its steady on and off states, but it dissipates considerable energy during times of a transition. Thus, it is desirable to switch as quickly as possible to minimize power dissipated. Because the MOSFET gate is basically capacitive, it requires appreciable current pulses to charge and discharge the gate in a few tens of nanoseconds. Peak gate currents can be as high as an ampere.

The high impedance of MOSFET inputs can lead to stability problems. Under certain conditions, high-voltage MOSFETs can oscillate at high frequencies because of stray inductance and capacitance in the surrounding circuit (frequencies usually in the low megahertz range). Device manufacturers recommend that a low-impedance gate-drive circuit be used to prevent stray signals from coupling to the MOSFET gate.

References

ON Semiconductor

onsemi.com

You may also like:

Ti Mosfet Vs

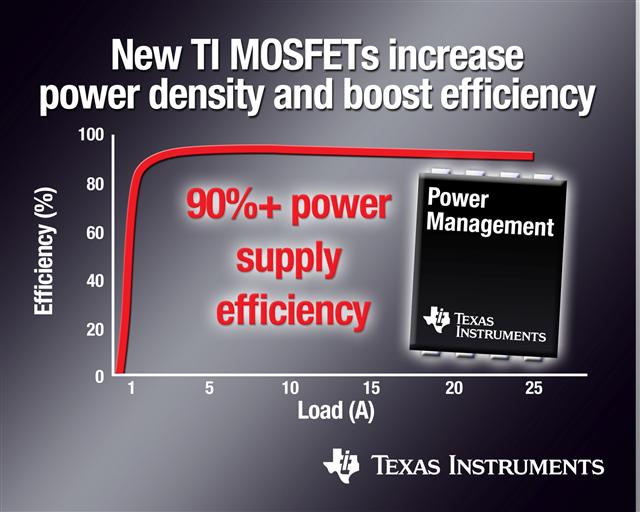

Delivering low gate charge and resistance for fast switching transistors

TI’s NexFET™ power MOSFETs offer a wide range of n-channel and p-channel power modules and discrete power supply solutions. Our highly-integrated MOSFETs support greater efficiencies, extended battery life, higher power density and higher frequencies for fast switching. These benefits provide design flexibility in small form factors and enable design engineers to reduce time to market.

Ti Mosfet Calculator

N-channel MOSFET transistor

We offer robust n-channel devices with class leading resistance and gate charge enabling high frequency operation and higher power density.

P-channel MOSFET transistor

Our p-channel devices deliver industry best power density and smallest footprints as well as easy to drive low gate charge.

Power stage MOSFET

Ti Mosfet Driver

Power stage combines integrated driver IC, optimized control and synchronous FETs while leveraging PowerStack™ packing technology to eliminate parasitics, reduce switching losses and achieve the highest efficiencies possible.

Power block MOSFET

Power blocks combine optimized control and synchronous FETs while leveraging PowerStack™ packing technology to eliminate parasitics and achieve high efficiency and switching frequencies.

Ti Mosfet Circuit

All of our MOSFET technical articles, app notes, videos and tools created to help you throughout every part of your design cycle.

High Power Mosfet

Receive fast and reliable technical support from our engineers throughout every step of your design.

MOSFET technical articles

Ti Mosfet Driver Application Note

| Title | Description |

|---|---|

| What does a “lead-free” power MOSFET really mean? | Learn about the nuances in the termninology 'lead free' and what you should actually be looking for. |

| Choosing the right SOA for your design: discrete FETs vs. power blocks | Learn the differences in how TI specifies SOA for single, discrete FETs vs. integrated power blocks. |

| FemtoFET™ MOSFETs: small as sand but it’s all about that pitch | Learn about the key benefits of our small FemtoFET™ MOSFETs. |

| Improve the performance of your power tool design with power blocks | Learn how a MOSFET power block helps to achieve a more reliable, smaller-sized, efficient and cost-competitive system solution. |

| MOSFET pair the size of a flake of pepper? | Learn how ultra-thin Power Block II devices allow products to become dense, while consuming less power and dissipating less heat. |

| Selecting the right power MOSFET/power block package for your application | Learn about package thermal capability and power dissipation in TI MOSFET and power block packages. |

| What’s not in the power MOSFET data sheet, part 1: temperature dependency | Learn about what is in a MOSFET data sheet and more importantly, what's not. |

| See all technical documents | |